Valves

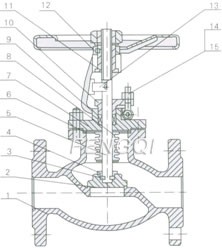

ANSI Bellow Seal Globe Valve

ANSI Bellow Seal Globe Valves

Summary

Stop valve with bellow seal acc.to ANSI is applicable to the cutting, switch and the adjustment of fluid.

Medium that is used in various industries such as petroleum, chemical industry, pharmacy,

Chemical fertilizer, electric power industry etc under nominal pressure of CLASS150-900LBS and working temperature of -29~350°C

Parabolic Plug for switch and the adjustment of fluid is available.

Features

1. This product has logical structure, reliable seal, excellent performance and nice design.

2. The seal surface is build-up welding with Co hard alloy, which is attrition-resistant, corrosion-resistant, has good friction resistant and long life.

3. The stem is quenched and tempered, and its surface is treated by nitrogen treatment, thus it is has good corrosion resistant and friction resistant.

4. It has double seal capability, thus is more reliable.

5. The stem may show the position of lift, thus it is clearer.

6. The part material, flange and butt weld end dimension may be selected according to current operating conditions and users' requirement, so that meet the requirements of various engineering.

Structural formation: BB-BG-OS&Y

Driving manner: Hand-operated, Electric-actuated

Specifications

Design: AP1600,AP16D

Face to face: ASME B16.10

Flange ends: ASME B16.5

Test&inspection:AP1598,AP16D

Performance Specification

| ASME Pressure Class | (MPa) Shell test | (MPa) Sealing test | (°C) Suitable temp | Suitable medium |

| 150 | 3.0 | 2.2 | =350°C | Water oil&gas |

| 300 | 7.5 | 5.5 | ||

| 600 | 15.0 | 11.0 | ||

| 900 | 22.5 | 16.5 |

Materials

Materials of ANSI Bellow Seal Globe Valves

| NO. | Part name | Material |

| 1 | Body | ASTM A216-WCB ASTM A351-CF8, CF8M, CF3, CF3M |

| 2 | Disc | ASTM A182-Gr.F6a, ASTM A182-F22 ASTM A182-F304, F316, F321, F304L, F316L |

| 3 | Split ring | ASTM A182-Gr.F6a, ASTM, A182-F22 ASTM, A182-F304, F316, F321, F304L, F316L |

| 4 | Disc bushing | ASTM A182-Gr.F6a, ASTM A182-F22 ASTM A182-F304, F316, F321, F304L, F316L |

| 5 | Stem | ASTM A182-Gr.F6a, ASTM A182-F22 ASTM A182-F304, F316, F321, F304L, F316L |

| 6 | Gasket | Flexible graphite+stainless steel, PIFE |

| 7 | Bonnet | ASTM A216-WCB ASTM A351-CF8, CF8M, CF3, CF3M |

| 8 | Bellows | ASTM A182-F304, F316, F321, F304L, F316L |

| 9 | Parking | Flexible Graphite, PTFE |

| 10 | Gland | ASTM A216-WCB ASTM A351-CF8, CF8M, CF3, CF3M |

| 11 | Yoke nut | ZQA19-4 |

| 12 | Handwheel | ASTM A536Gr.60-40-18, A216-WCB |

| 13 | Guiding piece | 45, WCB, 304, 316, 304L, 316L |

| 14 | Bolt | ASTM A193-B7, A193-B8, A193-B8M |

| 15 | Nut | ASTM A194-2H, A194-8, A194-8M |

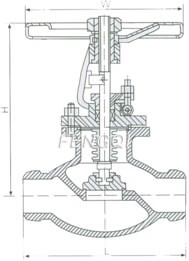

Dimensions and Weight

| Pressure | 150Lb | |||||||||||||||

| size | min | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 108 | 117 | 127 | 140 | 165 | 203 | 216 | 241 | 292 | 356 | 406 | 495 | 622 | 698 | 787 | |

| H | 241 | 241 | 241 | 280 | 286 | 368 | 387 | 400 | 457 | 520 | 609 | 698 | 762 | 876 | 990 | |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 320 | 340 | 400 | 450 | 450 | 450 | |

| Weight(kg) | 4 | 5 | 6 | 10 | 13 | 18 | 30 | 35 | 55 | 75 | 104 | 200 | 300 | 390 | 610 | |

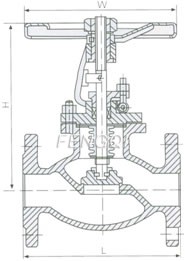

| Pressure | 300Lb | |||||||||||||||

| size | min | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 11/4 | 11/2 | 2 | 21/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 152 | 178 | 203 | 215 | 229 | 267 | 292 | 318 | 356 | 400 | 444 | 559 | 622 | 711 | 762 | |

| H | 241 | 241 | 283 | 320 | 322 | 399 | 438 | 450 | 584 | 610 | 660 | 762 | 850 | 1085 | 1187 | |

| W | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 280 | 300 | 320 | 340 | 400 | 450 | 450 | 450 | |

| Weight(kg) | 6 | 7 | 10 | 15 | 20 | 25 | 30 | 52 | 88 | 115 | 160 | 259 | 420 | 595 | 876 | |

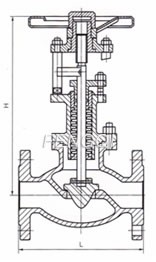

| Pressure | 600 Lb | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 165 | 190 | 216 | 229 | 241 | 292 | 330 | 356 | 432 | 508 | 559 | 660 | 787 | 838 | 889 | |

| H | 240 | 280 | 320 | 390 | 430 | 480 | 508 | 635 | 750 | 914 | 1016 | 1219 | 1330 | 850 | 1560 | |

| W | 140 | 140 | 160 | 160 | 180 | 180 | 250 | 250 | 350 | 400 | 450 | 500 | 600 | 720 | 760 | |

| (Kg)Weight | 7 | 10 | 16 | 22 | 29 | 35 | 50 | 90 | 150 | 230 | 300 | 510 | 850 | 1120 | 1400 | |

| Pressure | 900LB | |||||||||||||||

| Size | mm | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 |

| in | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | |

| L | 229 | 229 | 254 | 279 | 305 | 368 | 419 | 381 | 457 | 559 | 610 | 737 | 838 | 965 | 1029 | |

| H | 280 | 330 | 350 | 430 | 508 | 569 | 430 | 635 | 774 | 860 | 1040 | 1330 | 1560 | 1650 | 1780 | |

| W | 160 | 160 | 180 | 180 | 250 | 250 | 320 | 350 | 450 | 550 | 600 | 720 | 760 | 820 | 890 | |

| (Kg)Weight | 10 | 16 | 23 | 37 | 49 | 65 | 75 | 120 | 200 | 350 | 410 | 790 | 1300 | 1500 | 1800 | |