Valves

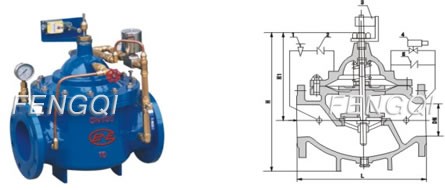

Pump Control Valves

700X Features

700X pump control valve is installed at the pump's outlet in high building and other feeding system to prevent fluid flowing backwards. Before the pump stops, the valve closes 90% or so ahead to prevent water hammering and water hitting at the pump's instant stop; after the pump completely stops, the valve closes fully to prevent fluid flowing backwards at the outlet of the pump to protect the pump and prevent it from turning backwards due to backward flow of the fluid. This is necessary protection equipment for the pump. It is flow-line designed and it can open or close to electric-magnetic valve's pilot. It is safe to use and it is easy to install and to maintain this kind of valve.

Pump Control Valves

1. Needle Valve 2. Check Valve 3. Stroke Switch 4. Solenoid Valve 5. Check Valve

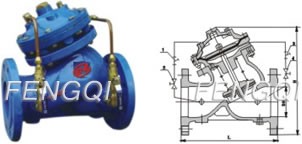

JD745X Features

JD745X pump control valve is mounted on the water pumps outlet pipeline of the high buildings and other water supply systems to prevent of the mediums back-flow and the water hammer and water shock.

JD745X pump control valve has good effect of water hammer removal. Integrating the technical principles of water hammer removal by means of slow open, quick close and slow close, so as to prevent of the water hammers at both pump start and stop.

Easy operation. The valve will open or close automatically as per the operation procedures of the pump, once operates the On-Off button of the pumps motor.

Good effect of energy saving. The valve body is designed as full-path straight-flow type, resulting in small pressure loss, big flow, small volume and light weight.

Diaphragm actuated

1. Strainer 2. Small Ball Valve 3. Strainer 4. Small Ball Valve

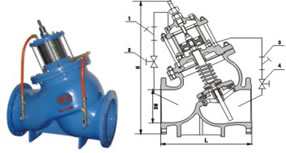

Piston actuated

1. Strainer 2. Small Ball Valve 3. Strainer 4. Small Ball Valve

Technical Parameters

Nominal Pressure: 1.0, 1.6, 2.5MPa

Shell test pressure: 1.5, 2.4, 3.75MPa

Sealed test pressure : 1.1, 1.76, 2.75MPa

Suitable temperature: 80

Suitable medium: water, Sewage

Materials

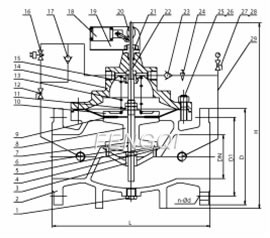

| No. | Part | Material |

| 1 | Plug | Alloy Bronze |

| 2 | Body | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 3 | Seat | 2Cr13 / SS 304 / SS 316 |

| 4 | O-Ring | NBR |

| 5 | O-Ring | NBR |

| 6 | O-Ring Retainer | Cast Iron |

| 7 | Stem | 2Cr13 / SS 304 / SS 316 |

| 8 | Disc | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 9 | Diaphragm | Rubber |

| 10 | Diaphragm washer | Cast Iron |

| 11 | Nut | Alloy Bronze |

| 12 | Ball valve | Alloy Bronze |

| 13 | Spring | Stainless steel |

| 14 | Cover | Cast Iron (GG25, HT200) / Ductile Iron (GG40, QT) |

| 15 | Pilot socket | Alloy Bronze |

| 16 | Solenoid valve | Alloy Bronze |

| 17 | One-way valve | Alloy Bronze |

| 18 | On/Off | |

| 19 | Yoke | Steel |

| 20 | Limitation piece | Alloy Bronze |

| 21 | Plug | Alloy Bronze |

| 22 | Metering | 2Cr13 |

| 23 | One-way valve | Alloy Bronze |

| 24 | Needle Valve | Alloy Bronze |

| 25 | Nut | Steel |

| 26 | Screw | Steel |

| 27 | Ball valve | Alloy Bronze |

| 28 | Pressure Gauge | |

| 29 | Connection Pipe | Alloy Bronze |

Dimensions

700X

| DNmm | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 700 | 800 | |

| L | 180 | 180 | 180 | 203 | 203 | 235 | 280 | 360 | 400 | 455 | 585 | 650 | 800 | 860 | 915 | 980 | 1075 | 1230 | 1300 | 1450 | |

| PN10 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 390 | 440 | 500 | 565 | 615 | 670 | 780 | 895 | 1010 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 | 460 | 515 | 565 | 620 | 725 | 840 | 950 | |

| PN16 | D | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 | 405 | 460 | 520 | 580 | 640 | 705 | 840 | 910 | 1020 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 355 | 410 | 470 | 525 | 585 | 650 | 770 | 840 | 950 | |

| PN25 | D | 105 | 110 | 135 | 145 | 160 | 180 | 195 | 230 | 270 | 300 | 360 | 425 | 485 | 550 | 610 | 660 | 730 | 840 | 955 | 1070 |

| D1 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 | 220 | 250 | 310 | 370 | 430 | 490 | 550 | 600 | 660 | 770 | 875 | 990 | |

| H | 342 | 342 | 342 | 395 | 395 | 405 | 430 | 510 | 560 | 585 | 675 | 730 | 760 | 840 | 910 | 1070 | 1135 | 1270 | 1460 | 1640 | |

| H1 | 247 | 247 | 247 | 278 | 278 | 298 | 313 | 350 | 365 | 420 | 450 | 470 | 490 | 526 | 570 | 610 | 665 | 725 | 865 | 975 | |

JD745X

| DN | L | D | D1 | n-d | H | ||||||

| 1.0Mpa | 1.6 (Mpa | 2.5 Mpa | 1.0Mpa | 1.6 Mpa | 2.5 Mpa | 1.0Mpa | 1.6 Mpa | 2.5 Mpa | |||

| 50 | 205 | 165 | 165 | 165 | 125 | 125 | 125 | 4-18 | 4-18 | 4-18 | 293 |

| 65 | 216 | 185 | 185 | 185 | 145 | 145 | 145 | 4-18 | 4-18 | 8-18 | 328 |

| 80 | 250 | 200 | 200 | 200 | 160 | 160 | 160 | 8-18 | 8-18 | 8-18 | 364 |

| 100 | 320 | 220 | 220 | 235 | 180 | 180 | 190 | 8-18 | 8-18 | 8-22 | 418 |

| 125 | 365 | 250 | 250 | 270 | 210 | 210 | 220 | 8-18 | 8-18 | 8-22 | 481 |

| 150 | 415 | 285 | 285 | 300 | 240 | 240 | 250 | 8-22 | 8-22 | 8-26 | 543 |

| 200 | 500 | 340 | 340 | 360 | 295 | 295 | 310 | 8-22 | 12-22 | 12-26 | 673 |

| 250 | 605 | 395 | 405 | 425 | 350 | 355 | 370 | 12-22 | 12-26 | 12-26 | 792 |

| 300 | 698 | 445 | 460 | 485 | 400 | 410 | 430 | 12-22 | 12-26 | 12-30 | 927 |

| 350 | 787 | 505 | 520 | 555 | 460 | 470 | 490 | 16-22 | 16-26 | 16-30 | 957 |

| 400 | 914 | 565 | 580 | 620 | 515 | 525 | 550 | 16-26 | 16-30 | 16-33 | 1188 |

| 450 | 978 | 615 | 640 | 670 | 565 | 585 | 600 | 20-26 | 20-30 | 16-36 | 1218 |

| 500 | 978 | 670 | 715 | 730 | 620 | 650 | 660 | 20-26 | 20-33 | 20-36 | 1256 |

| 600 | 1150 | 780 | 840 | 845 | 725 | 770 | 770 | 20-30 | 20-36 | 20-39 | 1600 |

| 700 | 1300 | 895 | 910 | 960 | 840 | 840 | 875 | 2430 | 24-36 | 24-42 | 1750 |

| 800 | 1450 | 1015 | 1025 | 1085 | 950 | 950 | 990 | 2433 | 24-39 | 24-48 | 1900 |

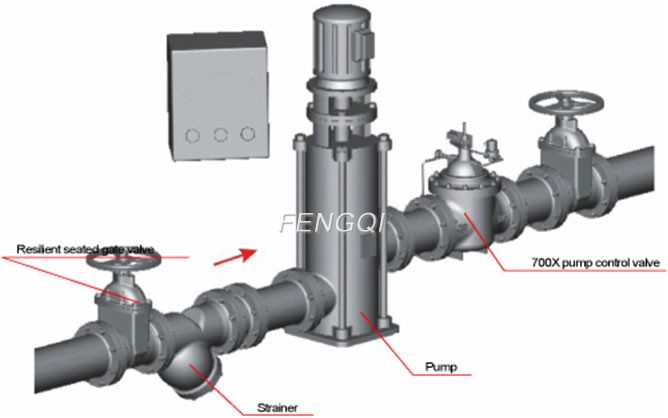

Typical Installation

700X

J745X