Valves

CV3000-HMT(HDT) Tee Confluence(shunt) Regulator

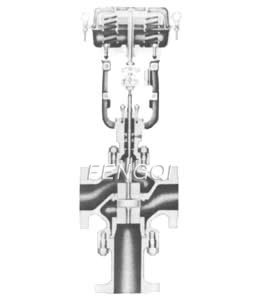

CV3000-HMT(HDT) Tee Confluence(shunt) Regulator

Structural features and applied range

CV3000-HMT(HDT) tee confluence(shunt) regulator: 3-way regulating valve is usually used in heat exchanger, regulating fluid temperature, with high precision, good regulative performance characteristics. Generally divide one inport fluid into two fluids, or compose two inport fluids into one export fluid. When nominal diameter and differential pressure are lesser, the confluence valve can be used for shunting, but for the nominal diameter larger than 80mm and larger differential pressure occasions, using the flow divider is more suitable.

The product conforms to the GB/T4213-92.

Technical parameters and performance indicators

body

body type: 3-way cast spherical valve

nominal diameter

HMT confluence valve:25、40、50、65、80、100、125、150mm

HDT flow divider:80、100、125、150mm

nominal pressure

ANSI: 150、300Lb

JIS: 10、20K

PN: 1.6、4.0MPa

connection

flange connection:FF、RJ

flange standard:JIS B2201-1984、ANSI B16.5-1981、JB/79-59 etc.

body material: cast steel(ZG230-450),cast stainless steel(ZG1Cr18Ni9Ti、ZG1Cr18Ni12Mo2Ti、ZG316L)

upper bonnet

normal temperature type(P):0~+200℃

extend I type(EⅠ):200~+425℃

gland type: bolt pressure type

Sealing packing V type PTFE packing, containing PTFE leached asbestos packing, asbestos weave packing, graphite packing

Internal components

core type: V type gap core

flow characteristics: linear

material: SS(1Cr18Ni9Ti、1Cr18Ni12Mo2Ti、17-4PH、9Cr18、316L), SS bead weld stellite, Ti and anti-corrsive alloy, etc

actuator

type: ZHA(B) multi-spring diaphram actuator

diaphragm material: NBR with nylon

spring range 20~100、80~240KPa

air supply pressure 140~400KPa

air source interface Rc 1/4

environmental temperature -30~+70℃

valve acting type: pneumatic close or pneumatic open type

Annex locator, air pressure filter, position valve, stroke switches, the transmitter, handwheel mechanism, etc

performance

leakage :less than 0.01% of rated volume,in accordance with ANSI B16.104-1976 class Ⅳ

return difference

with positioner: less than 1% of full stroke

without positioner: less than 3% of full stroke

intrinsic error

with positioner: less than ±1% of full stroke

without positioner: less than ±5% of full stroke

Note: using normal V type PTFE packing

adjustable range 25:1