Valves

Self-reliance Flow Regulator

Self-reliance Flow Regulator

Features

ZZYP, ZZYM type self-reliance flow regulator is an energy saving control device that without needing drive power, rely on the media itself pressure as power supply and its media pressure change, automatically control according to the setting value. It integrates detection and control, implement many functions in one valve, forming an independent instrument control system.

This product is consist of low flow resistance single seat (sleeve) valve body, pressure balance parts, command and actuators.

It is a new generation valve that conforms to international standards, the characteristics are:

1, without the external driving power energy-saving self-control system, low cost.

2 simple structure, small maintenance workload.

3, the setting point can be adjustable and with a wide range, convenient for the user to stepless adjust flow within the setting range,

4 command operating responses more quickly compared with direct effect dynamic model. With high precision, large adjustable ratio.

5, valve uses pressure balance mechanism, makes the regulator senstive reaction, accurate control, allowing large pressure differential.

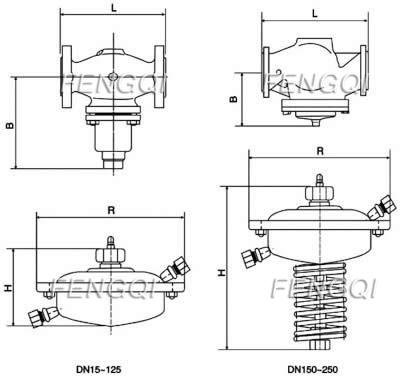

External dimensions

Self-reliance Flow Regulator Structures

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | |

| rated flow coefficient Kvs | 4 | 6.3 | 8 | 16 | 20 | 32 | 50 | 80 | 125 | 160 | 280 | 320 | 400 | |

| PN MPa | 1.6;4.0 | |||||||||||||

| effective pressure max. flow(m3/h) | 0.02MPa | 1.5 | 2.5 | 3.5 | 5.5 | 9.0 | 14 | 22 | 36 | 55 | 70 | 125 | 180 | 250 |

| 0.05 MPa | 2.5 | 3.5 | 5.5 | 9.0 | 12 | 22 | 36 | 55 | 85 | 110 | 180 | - | - | |

| niose measuring coefficient value Z | 0.6 | 0.6 | 0.6 | 0.55 | 0.55 | 0.5 | 0.5 | 0.45 | 0.4 | 0.35 | 0.3 | 0.2 | 0.2 | |

| max. working temperature ℃ | ≤140 | |||||||||||||

| hard sealing equipped with isolating tank ≤200 | match isolating extend part ≤200 | |||||||||||||

| pressure balanced components | bellows | scroll diaphragm | ||||||||||||

| flange standard | ANSI、JIS、DIN、GB、JB(special can according to customers’ requirement) | |||||||||||||

| body material | cast iron, cast steel, cast stainless steel | |||||||||||||

| core material | S.S. soft sealing is SS inlay rubber ring | |||||||||||||

| max. working pressure | PN (pay attention to △Pmax and working pressure and temperature relationship) | |||||||||||||

Main technical parameters

| effective area(cm2) | 250 | 630 |

| effective pressure (MPa) | 0.02;0.05 | |

| allowed pressure differential between upper and lower diaphragm chamber (MPa) | 0.4 | 0.15 |

| material | :diaphragm cover steel plate galvanizing; diaphragm:EPDM or FKM clip with fibre | |

| control pipeline, joint | copper pipe or steel pipe | |

Performance indicators

| control accuracy | ±5% | |||

| allowed leakage(under required test condition) | soft sealing | 4×10-4 rated volume | ||

| hard sealing | DN15~50 | DN65~125 | DN150~250 | |

| 10 bubble/min | 20 bubble/min | 40 bubble /min | ||

Allowed pressure differential

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | |

| Max. allowed pressure differential △P(MPa) | PN16 | 1.6 | 1.5 | 1.2 | 1.0 | |||||||||

| PN40 | 2.0 | |||||||||||||

External dimensions and weight

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 |

| L mm | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 | 730 |

| B mm | 121 | 212 | 238 | 238 | 240 | 240 | 275 | 275 | 380 | 380 | 295 | 325 | 372 |

| φR mm | 263 | 380 | |||||||||||

| H mm | 150 | 520 | |||||||||||

| weight(kg) | 21 | 23 | 24 | 27 | 31 | 36 | 47 | 55 | 74 | 93 | 118 | 178 | 261 |